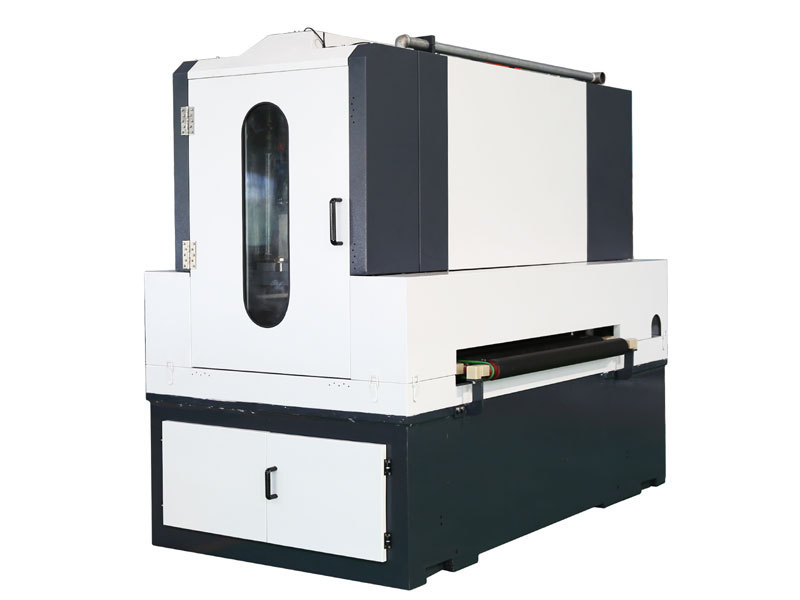

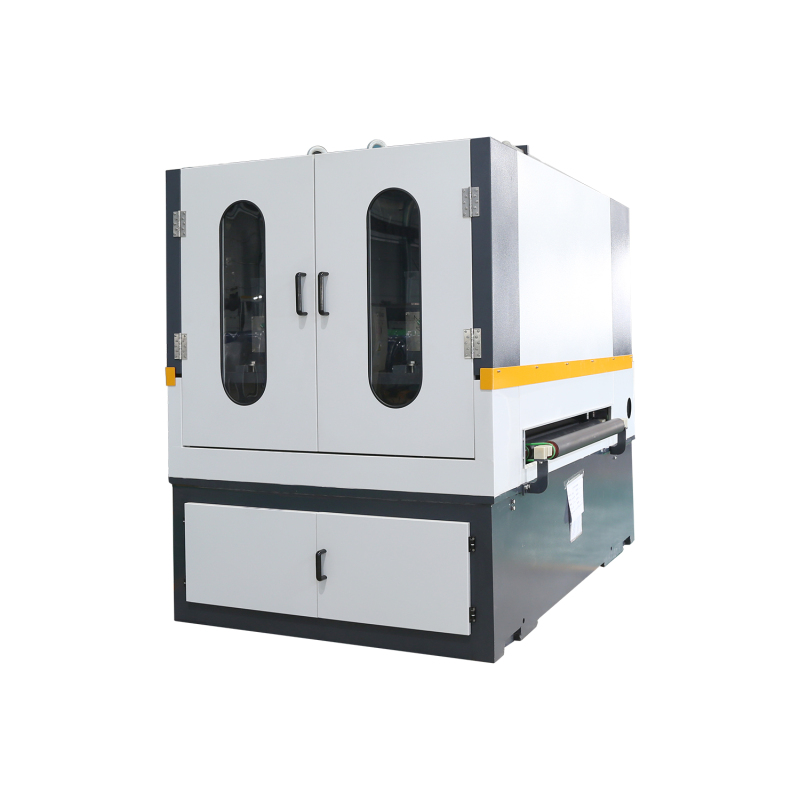

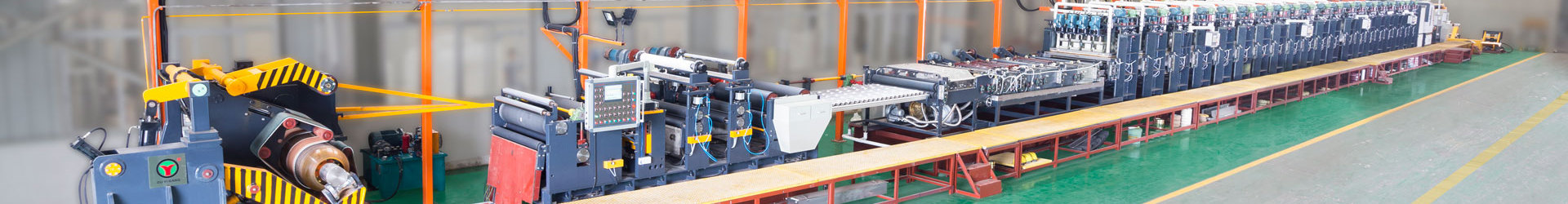

Máy mài cuộn dây thép không gỉ mài mòn

Bàn chải nhiều đầu, thiết bị “tất cả trong một dòng” với No.4—No.6 , Scotch-Brite , Hairline

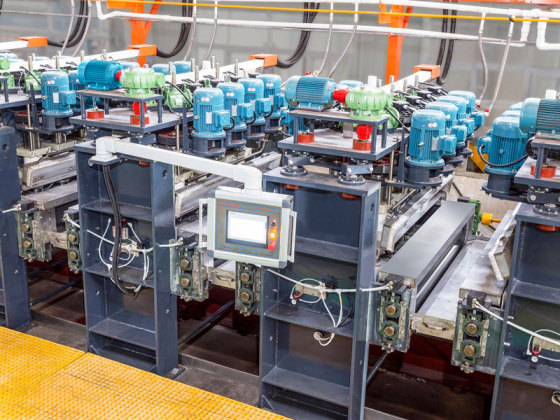

Điều khiển bằng PLC hoàn chỉnh với màn hình cảm ứng

Hầu hết các công trình bên trong được làm bằng thép không gỉ cường lực

Hệ thống quay và dao động trục ngang

Bề mặt mềm mại, tươi sáng và đồng nhất

hỗn hợp dầu và nước, xử lý kiểu ướt

Áp lực đánh răng có thể điều chỉnh

Điều chỉnh tốc độ bàn chải

Dễ dàng thay thế con lăn bàn chải mài mòn

Điều chỉnh tốc độ băng tải (đai / con lăn)

Có thể kết hợp các loại bàn chải khác nhau để thực hiện xử lý bề mặt khác nhau

Công tắc an ninh khẩn cấp

Tốc độ băng tải đảo ngược để kiểm soát khẩn cấp

- OUYIGANG

- PHẬT SƠN

- Một tháng

- 1 Bộ/ Tháng

- thông tin

- Video

Thành phố: Phật Sơn

Tỉnh: Quảng Đông

Quốc gia:Trung Quốc

Basic specification for the machine

Belt abrasive station | No.4 | Hairline | |

Brush abrasive station | SB | ||

System | Wet roller grinding | Wet roller brushing | Wet roller grinding |

No. of working unit | 2-3 grinding heads | 2-4 polishing heads | 2-3 grinding heads |

Machine weight | Appro 13T | 11T | 13T |

Working width | 900,1250,1500mm, , customized available | ||

Sheet size | 1250X2500mm 1550X3000mm customized available | ||

Sheet thickness min / max | 0.3-4mm | 0.3-4mm | 0.3-4mm |

Roller dimensions(Od X width) | 300mm | 350mm | 250mm |

Abrasive belt width | Depending on the sheet width

| ||

Abrasive belt length | 2620mm | 2620mm | |

Speed of the line | 6-25M/min | 6-25M/min | 6-25M/min |

Processing capability

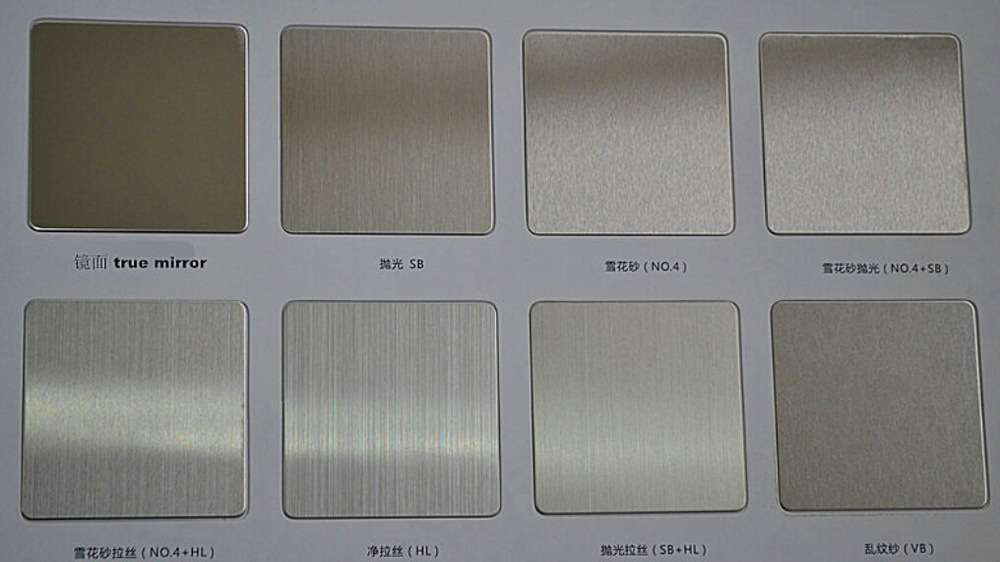

No.4 finish

The basic sheet selection is to be of 2B or BA sheet and should be preferably polished with 150#,180# abrasive belt. The application verticals of this finish to name a few are in cookware, furniture, elevator, architectural decoration, revolving door, exterior decoration etc,.

HAIRLINE finsh

The basic sheet selection should preferably be of No.4 satin surface stainless steel sheet and should be subjected to polish with 150# 240#abrasive belt. The application verticals of this finish to name a few are in elevator, architecture decoration, revolving door, furniture, home appliance, auto sector, exterior decoration, etc,.

Scotch Brite-Satin finish

The basic sheet selection should preferably be of No.4 satin surface stainless steel sheet and should be subjected to polish with abrasive wheels or pads. . The application verticals of this finish to name a few are in architecture decoration, elevators and escalators, furniture, etc,.

No.6 finish

These finishes are produced using rotating cloth mops (tampico fibre,muslin or linen) which are loaded with abrasive paste.The finish depends on how fine an a abrasive is used and the uniformity and finish of the original surface. The finish as a non directional texture of varing reflectivity.Satin blend is an example of such a finish.

No.7 finish

This is a buffed finish having a high degree of reflectivity.It is produced by progressively using finer and finer abrasives and finishing with buffing compounds. Some fine scratches may remain from the original starting surface.

No.8 true mirror finish

This is produced in an equivalent manner to a No.7 finish, the final operation being done with extremely fine buffing compounds. The final surface is blemish free with a high degree of image clarity and is the true mirror finish.

No.9 super mirror finish

Very high degree of reflectivity, brilliant, smooth finish produced by polishing with progressively finer grit abrasives then buffing. Super mirror creates light and space. Best for design, decoration and architecture.

Multi head brushing station, “all in one line ” equipment with No.4—No.6 , Scotch-Brite , Hairline finish

Control by PLC complete with touch screen

Most of the inside construction is made of tempered stainless steel

Horizontal axis rotating and oscillating system

Soft, bright and homogeneous surface appearance

oil and water mixed ,wet type processing

Adjustable brushing pressure

Adjustable brush speed

Easy abrasives brush roller replacement

Adjustable conveyor speed (belt / roller)

Different brush grits combinations are possible to perform different surface treatment

Emergency security switch

Reversal conveyor speed for emergency control

Picture Shows

Packaging & Shipping

Packaging: all of the machine, equipment and spare parts spray the rustproof oil, cover with oil paper and plastic film.

Shipping: arrange technical workers to load the machine with crane , fixed the machine to the container with strong steel rope, and guarantee your machine shipped to your port without any human causing damage.

Cooperation company

Our Services

After-sale service:We supply life time technique service to our customer and just charge basic cost for comsumable parts.

FOSHAN OUYIGANG engaged in design and manufacturing the stainless steel surface processing machinery,the factory of OUYIGANG occupies above 12000 square meters, we are the high-tech company of more than 15years production history, which gather science research,design,produce,sale install,adjust and maintenance.

Our company culture: loyalty,dedication, hard-work and cooperation

Company philosophy:Constant cooperation and mutual benefit, to create greater value for our customers.

Our service concept: Your little case is our big events.

The miss of our company: To pursuit perfect quality, then provide professional service.

Company vision: Building one centennial corporation, setting one international brand.

Company core value:

Observe disciplines and obey laws

Conscientious and love in work

Diligent and eager to learn

Cooperation and innovation

Contact us

Tel:86-757-88627213

Mobile phone:+86-13425703089

Address detail :Factory No.19,Xingliang Road, Sanzhou Town, Hecheng Street,Gaoming District, Foshan City,Guangdong Province,China.

City: FoShan

Province:GuangDong

Country:China